In the heating without burning technology, it can be divided into contact type and non-contact type according to whether the heating element is in direct contact with the heated substrate. The contact type includes central heating and circumferential heating, and the non-contact type includes air heating and infrared heating.

The core difference between contact and non-contact heating technology lies in the way heat is transferred, which directly affects the heating efficiency, user experience and technology development direction.

1. Contact heating technology

接触式加热是Heat conduction is achieved by direct contact of the heating element (such as metal sheet, needle-shaped heating element) with the tobacco. The advantage is high heating efficiency. The disadvantage is that uneven heating is prone to occur. At the same time, the heating sheet is in direct contact with the tobacco substrate, which is prone to produce tar and other dirt.

According to the shape of the heating element, it is divided into central heating and circumferential heating.

a. Central heating

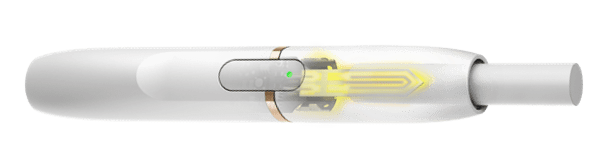

Center heating means that the heating element (such as ceramic needles, metal sheets) is directly embedded in the cigarette cartridge or close to the tobacco material. The heat is transferred from the inside to the outside, the heat source is in direct contact with the tobacco, and the heat utilization rate can reach 90%.

The typical representative of central heating is IQOS, whose heating element has gone through two stages of development:

- The first is the ceramic resistor, which has been updated from the first generation to the fifth generation. Although the heating efficiency is very fast, the ceramic heater has problems such as easy breakage and difficult cleaning;

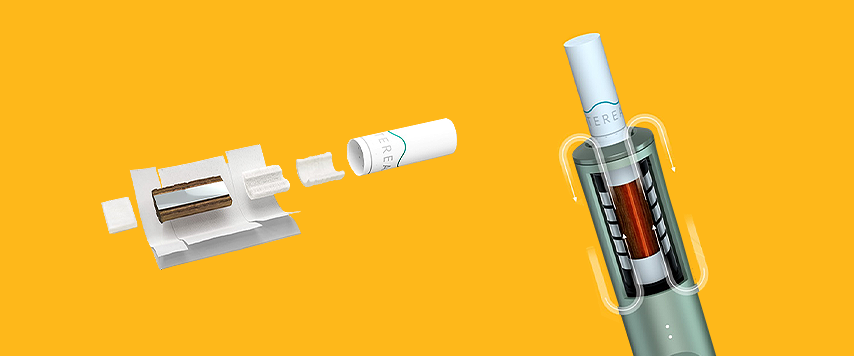

- The second is the electromagnetic induction metal sheet, which is used with IQOS ILUMA (also known as the sixth-generation machine), which perfectly solves some of the disadvantages of ceramic heating sheets, such as no longer needing regular cleaning. PMI has also further consolidated its leading market position.

电阻陶瓷片,IQOS

韩国烟草lil

电磁感应金属片,IQOS

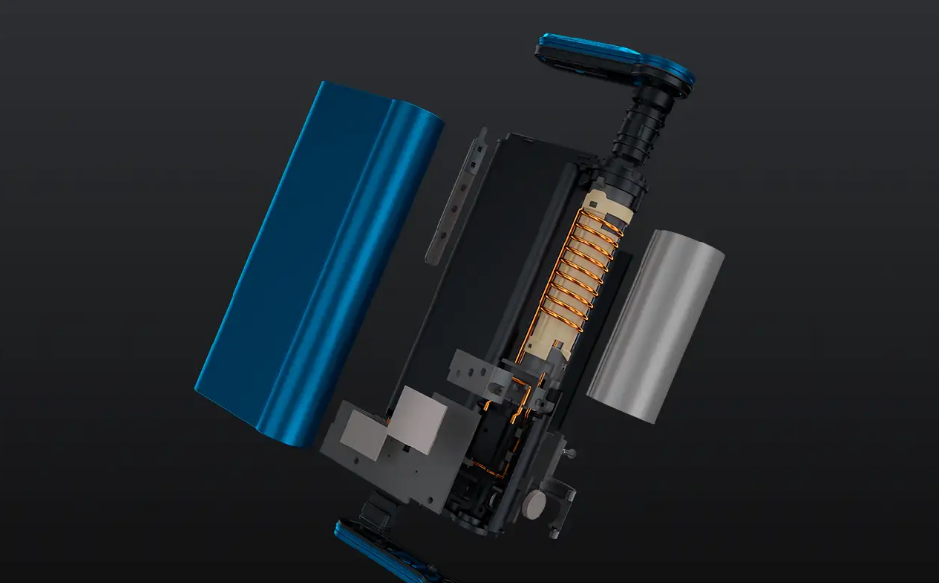

b. Circumferential heating (resistance)

The basic principle of contact circumferential heating is resistive heating. The heating element is made into a cup shape, wrapping the outside of the cigarette cartridge, transferring heat from the outside to the inside. The thermal efficiency is slightly lower than that of central heating (about 80-85%). Representatives include BAT Glo and JTI Ploom series.

英美烟草Glo

日本烟草Ploom

2. Non-contact heating technology

Non-contact heating means that the heating element does not directly contact the tobacco substrate, but generates hot air and heat radiation to heat the tobacco substrate. Currently, there are mainly air heating, infrared heating, light heating, etc. on the market. The advantage of non-contact heating is that the heating is more uniform and does not require cleaning. The disadvantage is that the heating efficiency is slightly inferior to contact heating.

a. Air heating

Air heating, also known as hot air heating, is a method of rapidly heating the air through the bottom ceramic heating element, which then flows through the cigarette cartridge for heating. It can simulate the traditional combustion process, gradually heat the tobacco stick, and avoid overheating of the core. Representative brands include HEEZY and other brands. It is the most market-oriented non-contact heating technology in the industry. It is understood that many companies have already made layouts.

空气加热器具

空气加热器具

b.Infrared heating

Infrared heating, also known as infrared radiation heating, uses the radiation of infrared rays to resonate the molecules and atoms inside the heated object, thereby generating heat energy. Infrared heating has the advantages of strong penetration, uniform heating, high thermal efficiency, and no pollution, but the heating efficiency may be slightly inferior to resistance and electromagnetic heating in heat conduction. Cases include ihea.

红外加热器具,安徽中烟ihea

c.Light Heating

The representative of light heating technology is FIRSTUNION. The core breakthrough of Alkaid technology lies in its light heating method, which uses full-band light waves similar to sunlight to achieve fast and uniform heating. In addition to fast preheating, Alkaid has also achieved significant improvements in taste and health.

It can be seen that compared with the contact technology route dominated by international giants, domestic companies focus on non-contact fields such as air heating, infrared radiation, and light heating, breaking the patent blockade through differentiated innovation. In the wave of heating without burning technology iteration, Chinese companies are expected to use non-contact heating as a breakthrough point to set off a technological revolution of "overtaking on a curve".

来源:艾邦综合整理

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.