-

烟油黏度普遍较低:60-150Pa·s,黏度越低,电子烟漏油的风险较高,炸油声越大,用户体验差。 -

由于烟油与雾化芯长期接触,并频繁被加热,势必会导致口味衰减,导致用户体验差。 -

由于香精被高温加热,增加了产生有害物质的风险,而气溶胶中有害物质大多数是由香精高温产生,从而增加了国外对中国电子烟安全性的评估风险。

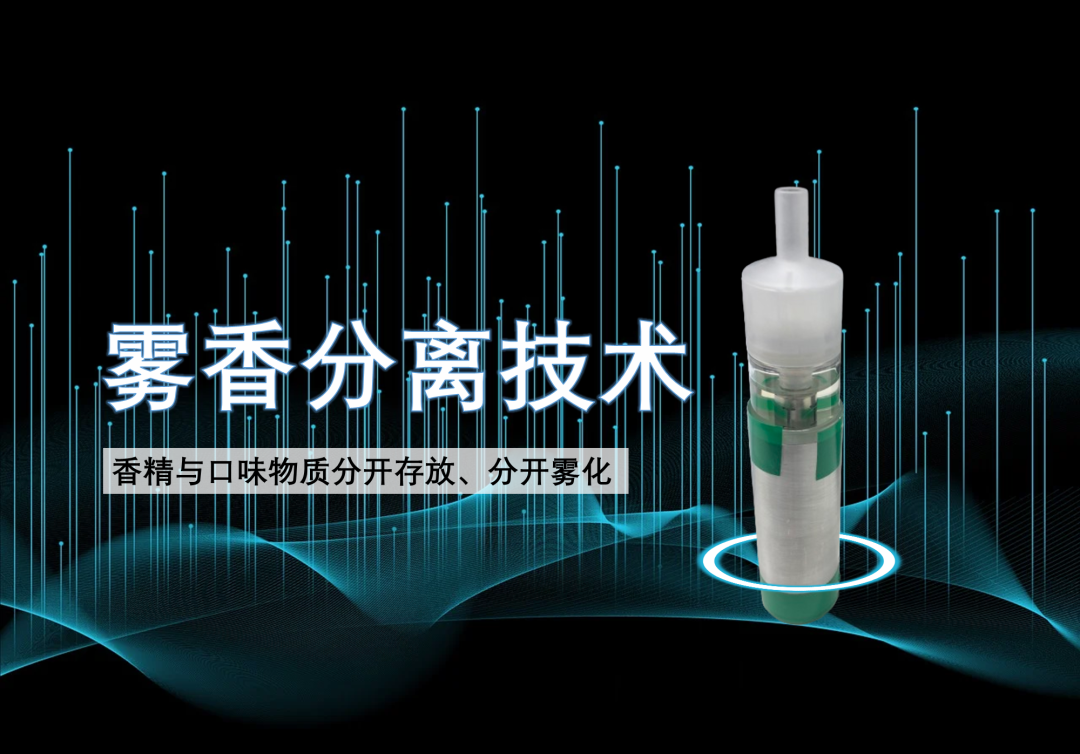

5 major advantages of electronic cigarettes with mist and aroma separation technology:

-

The viscosity of the e-liquid can be adjusted to 300-600Pa·s, which is much greater than the viscosity of existing e-liquid. Under the same electronic cigarette device, there is almost no oil leakage and no oil explosion, which reduces the sealing difficulty of the existing oil tank and the manufacturing cost, and provides good experience for both manufacturers and users. -

Since the flavor is atomized at room temperature, it will not cause flavor degradation and the user experience is good. -

Since the flavor is not heated, the risk of harmful substances produced by high temperature in the flavor is greatly reduced. Almost no harmful substances are produced, which makes consumers healthier and safer, and makes it easier to pass foreign assessments on the safety of Chinese e-cigarettes. -

Consumers can freely choose the type of aroma at low cost, match and switch at will, which increases the playability and entertainment of e-cigarettes. -

Increase the effective smoke volume by 30-50%, making the visible aerosol smoke atmosphere denser and providing a better user experience.

原文始发于微信公众号(艾邦新消费电子资讯):Introduction to electronic cigarette flavoring and mist aroma separation technology

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.