Fiberglass board A surface texture process

Since conventional fiberglass boards are opaque, the decorative effect of the fiberglass back cover is done on the surface, also called the A side. Different decorative layers are superimposed from bottom to top to achieve a colorful texture effect. The texture design can be an external texture or a combination of internal and external double textures.

外纹理工艺流程:

双纹理+镀膜的工艺流程:

PU leather or silicone leather can be laminated on the surface of fiberglass board, which can not only enhance the appearance of mobile phones, tablets and other consumer electronic products, but also bring excellent touch. Fiberglass board can be laminated after forming, or it can be formed in one piece at the same time of hot pressing.

成型后贴皮工艺流程:

一体成型工艺流程:

The rubbing process can directly print textures on the coating liquid, reducing the cost of film transfer, and reducing the film sticking and tearing processes, reducing labor costs.

工艺流程:

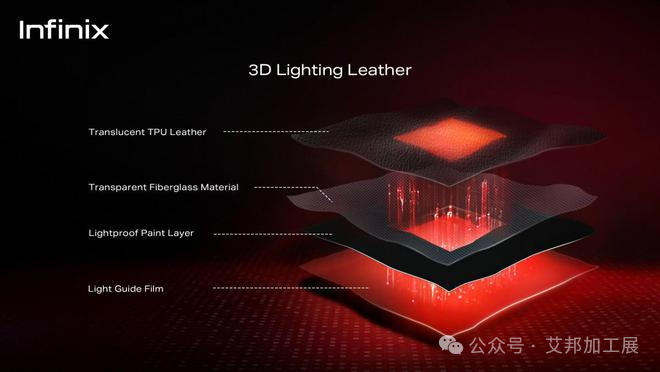

.It can achieve the colorful effect of optical texture and the touch of leather. Transparent leather can also be combined with light to create a unique sense of technology.

工艺流程:

原文始发于微信公众号(雾化科技展):Four surface decoration processes of fiberglass back cover

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.