很多电子烟研发反馈说希望引进跨界技术,因此后续会不定期更新来自跨界的技术文章分享,以供大家参考。如果有这类技术分享信息,可投稿至 ab033@aibang.com。

This article shares a material that is both high-strength and light—PBO fiber, which can achieve a thinner design while ensuring sufficient strength, and can be used as a reference for the miniaturization and lightweight design of e-cigarettes.

Since its launch in 2019, the thickness and lack of portability have always been the pain points that foldable screen mobile phones urgently need to solve. Therefore, in the past few years, major terminals have been continuously optimizing materials and structural designs to significantly reduce the thickness and weight of the body, in order to make the thickness and weight of foldable screen mobile phones infinitely close to those of straight-screen flagship mobile phones. For example, the Honor Magic V3, which has a super-thin body of 9.2mm in a folded state, has set a new record for the thickness of foldable screen mobile phones.

△ 2024年发布的大屏折叠手机厚度与重量统计

The Honor Magic V3 is so thin and light thanks to the new Luban architecture. In addition to the 2.84mm ultra-thin Luban shield steel hinge, the ultra-large capacity battery with an average thickness of 2.6mm, the cicada-wing pure titanium heat dissipation VC as thin as 0.22mm, the ultra-thin high-performance speaker with a single thickness of only 1.8mm, and the new 7 series high-strength aviation aluminum middle frame, it also pioneered the use of aerospace special fiber - PBO fiber in the velvet black version of the Honor Magic V3 mobile phone back cover, achieving a thinner design while ensuring sufficient strength.

△ 2024年发布的大屏折叠手机厚度与重量统计

The Honor Magic V3 is so thin and light thanks to the new Luban architecture. In addition to the 2.84mm ultra-thin Luban shield steel hinge, the ultra-large capacity battery with an average thickness of 2.6mm, the cicada-wing pure titanium heat dissipation VC as thin as 0.22mm, the ultra-thin high-performance speaker with a single thickness of only 1.8mm, and the new 7 series high-strength aviation aluminum middle frame, it also pioneered the use of aerospace special fiber - PBO fiber in the velvet black version of the Honor Magic V3 mobile phone back cover, achieving a thinner design while ensuring sufficient strength.

△ 绒黑色版本荣耀Magic V3

△ 绒黑色版本荣耀Magic V3

1. PBO fiber and its application advantages in consumer electronics such as foldable screen mobile phones

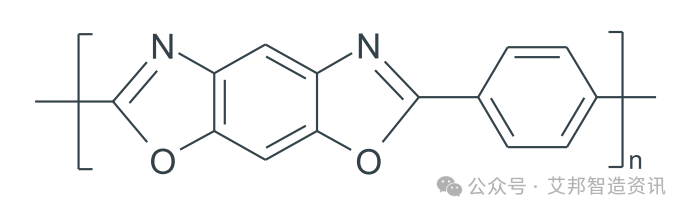

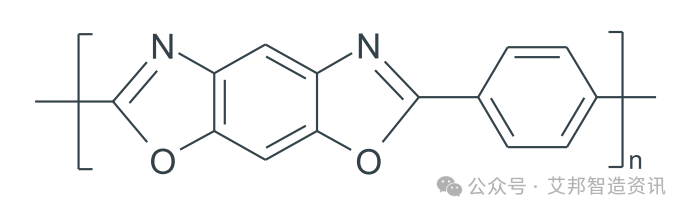

PBO fiber, the abbreviation of Poly-p-phenylene benzobisoxazole, is an organic reinforcement material designed and developed in the United States in the 1980s for the development of aerospace composite materials. It is a fiber containing heterocyclic aromatic The most promising variety in the polyamide family, it is known as the super fiber of the 21st century.

△ PBO分子结构

△ PBO分子结构

Structurally, PBO is a unique conjugated rigid rod-shaped molecule with a highly symmetrical molecular structure. Due to its unique molecular structure and special manufacturing process, PBO fiber has the characteristics of ultra-high strength, ultra-high modulus, high temperature resistance and high environmental stability. Its comprehensive performance is the best among organic fibers.

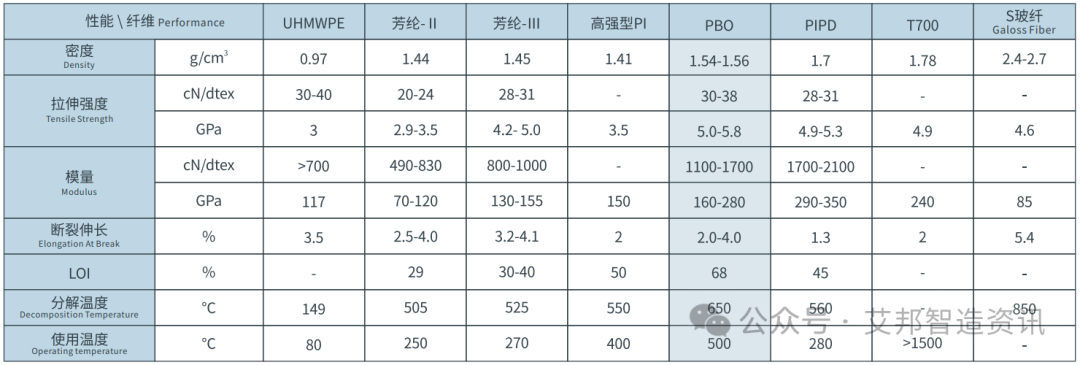

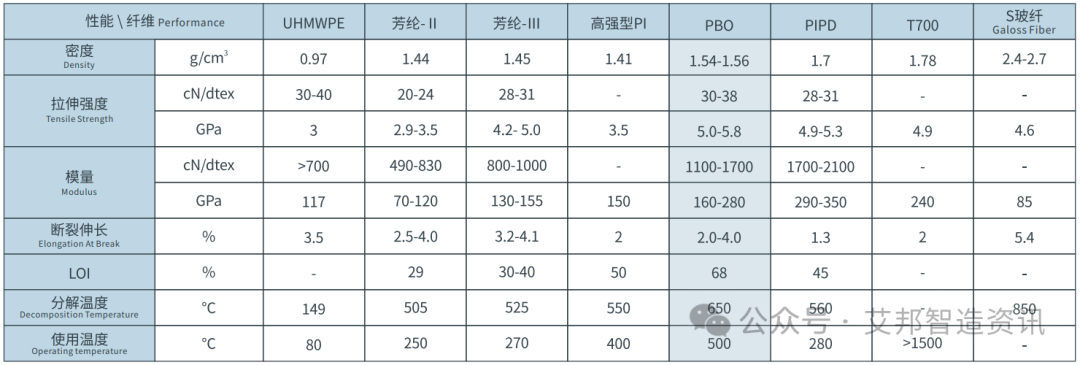

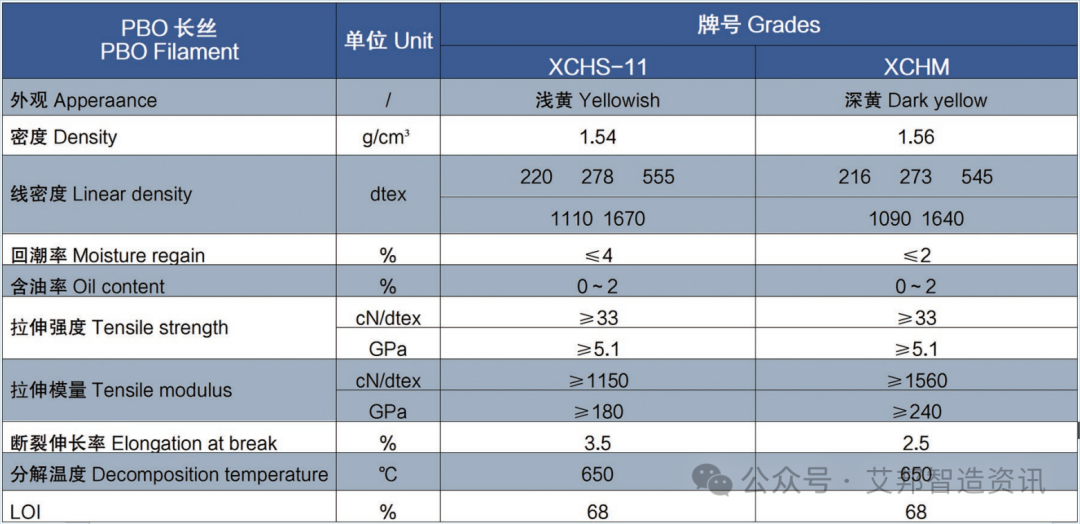

△ 中蓝晨光STARAMID® CG-PBO纤维与其他高性能有机纤维性能对比

The tensile strength and modulus of PBO fiber are almost twice that of para-aramid, and its heat resistance is 100℃ higher than that of para-aramid. Its limiting oxygen index (LOI) is 68%, and its decomposition temperature is as high as 650℃. It is a high-strength non-combustible fiber with a density of 1.54-1.56g/cm³, which is lower than that of carbon fiber and glass fiber. It has the characteristics of light weight and high strength. Based on its excellent performance, PBO fiber has important applications in high-end equipment and military industry, aviation industry, safety protection, electronic and electrical, transportation, construction materials, sports equipment and high-temperature filtration.

In the field of consumer electronics, PBO fiber has excellent dielectric properties (wave transmittance can reach more than 98%), mechanical properties, impact resistance and flame retardant properties. As a material for mobile phone structural parts, it will not interfere with communication signals. Compared with glass fiber boards, composite boards, glass and other materials, it can be designed to be thinner and lighter while ensuring structural strength. It is an ideal new material for ultra-light and ultra-thin design of consumer electronic products.

△ 中蓝晨光STARAMID® CG-PBO纤维与其他高性能有机纤维性能对比

The tensile strength and modulus of PBO fiber are almost twice that of para-aramid, and its heat resistance is 100℃ higher than that of para-aramid. Its limiting oxygen index (LOI) is 68%, and its decomposition temperature is as high as 650℃. It is a high-strength non-combustible fiber with a density of 1.54-1.56g/cm³, which is lower than that of carbon fiber and glass fiber. It has the characteristics of light weight and high strength. Based on its excellent performance, PBO fiber has important applications in high-end equipment and military industry, aviation industry, safety protection, electronic and electrical, transportation, construction materials, sports equipment and high-temperature filtration.

In the field of consumer electronics, PBO fiber has excellent dielectric properties (wave transmittance can reach more than 98%), mechanical properties, impact resistance and flame retardant properties. As a material for mobile phone structural parts, it will not interfere with communication signals. Compared with glass fiber boards, composite boards, glass and other materials, it can be designed to be thinner and lighter while ensuring structural strength. It is an ideal new material for ultra-light and ultra-thin design of consumer electronic products.

△ 荣耀Magic V3不同版本机身尺寸与重量信息

△ 荣耀Magic V3不同版本机身尺寸与重量信息

1998年,日本东洋纺公司实现PBO纤维的商业化生产,注册商标为Zylon,此后很长时间,东洋纺都是世界上唯一一家可以进行PBO纤维商业化生产的公司。

我国PBO纤维行业起步较晚,且由于合成PBO的单体4,6-二氨基间苯二酚盐酸盐(DAR)不能自产,完全依赖进口且价格高昂,加之国外对DAR垄断和禁售,国内对PBO纤维的研究进展缓慢。为了填补这一空白,国内多家科研机构和企业对PBO聚合工艺、PBO纤维的制备等关键技术进行攻关,经过10多年的不断研发,在PBO纤维的研制方面取得了显著进展,已实现了PBO纤维在国内的商业化量产。

1. 中蓝晨光化工研究设计院有限公司

官网:http://www.lxcgy.chemchina.com/

21世纪初,中蓝晨光在特种有机纤维研究基础上进⾏了PBO纤维的国产化开发,历经十余年研发生产,在国内率先实现了产品的批量供应。⽬前,中蓝晨光打造了国内PBO产品规格最⻬全,性能最优异的良好口碑,产品质量得到下游客户广泛认可,可以满足国内各领域用户的高端需求。

在消费电子领域,中蓝晨光化工研究设计院有限公司的STARAMID® CG-PBO纤维产品已应用于某国产品牌折叠屏旗舰手机的增强结构,助力该手机刷新折叠屏手机轻薄新纪录。

△ 中蓝晨光院PBO纤维

△ 中蓝晨光院PBO纤维

2. 成都新晨新材料科技有限公司

官网:http://www.cdsechin.com/zn/index.html

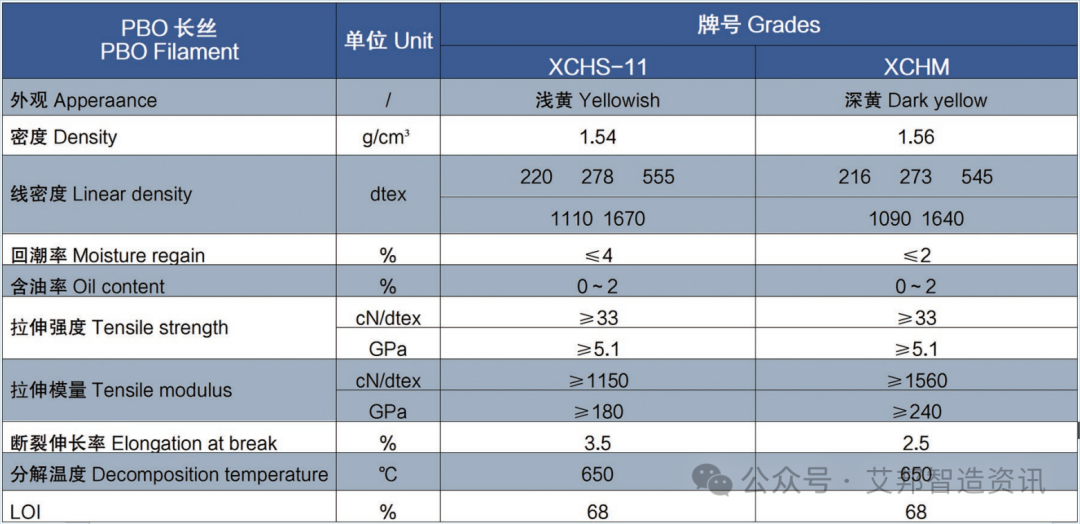

成都新晨新材科技有限公司成立于2016年,目前已建成380吨/年的PBO生产线,产能位居行业前列。

新晨新材以“侯德纶Houdelen”为主导品牌,生产销售PBO长丝、短切、短纤、浆粕、基布及预浸料等产品,同时具备PBO纤维表面处理、编织纺织等能力。PBO纤维在航空航天、国防军工、警用消防装备、轨道交通、电子通讯以及民用防护等领域均有广泛应用前景,是典型的军民两用材料。

△ 新晨新材侯德纶® PBO长丝

△ 新晨新材侯德纶® PBO长丝

3. 中科金绮新材料科技有限公司

中科金绮新材料科技有限公司引进中科院化学所关于高性能PBO纤维制备的专利技术,2018年成功建成年产100吨高性能PBO纤维生产线,实现了高性能PBO纤维的工业化批量生产,成为国内领先的高性能PBO纤维专业生产供应商。目前相关产品已在航空航天、国防军工、通讯电子、体育用品等领域得到了广泛应用。

原文始发于微信公众号(艾邦新消费电子资讯):High strength and lightness - Introduction to PBO fiber and its related suppliers

△ 2024年发布的大屏折叠手机厚度与重量统计

△ 2024年发布的大屏折叠手机厚度与重量统计 △ 绒黑色版本荣耀Magic V3

△ 绒黑色版本荣耀Magic V3 △ PBO分子结构

△ PBO分子结构 △ 中蓝晨光STARAMID® CG-PBO纤维与其他高性能有机纤维性能对比

△ 中蓝晨光STARAMID® CG-PBO纤维与其他高性能有机纤维性能对比 △ 荣耀Magic V3不同版本机身尺寸与重量信息

△ 荣耀Magic V3不同版本机身尺寸与重量信息

△ 中蓝晨光院PBO纤维

△ 中蓝晨光院PBO纤维

△ 新晨新材侯德纶® PBO长丝

△ 新晨新材侯德纶® PBO长丝