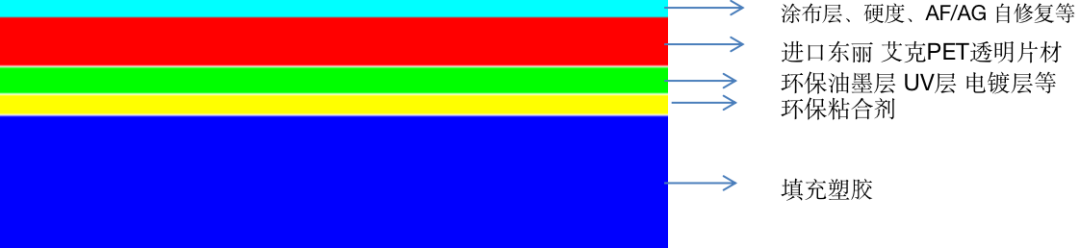

Definition ofIn Molding Label (IMD/IML) Process: The process utilizes a PET substrate that has been coated to meet specific surface requirements. Ink patterns are printed onto the substrate, followed by the application of an adhesive and curing of the ink. Subsequently, the substrate undergoes heating and baking to achieve thermal pressing and trimming. The shaped PET is then manually or mechanically placed into the injection mold cavity, where plastic is injected. Under high temperatures, the adhesive melts, bonding the ink layer on the PET sheet with the plastic to form a cohesive unit.

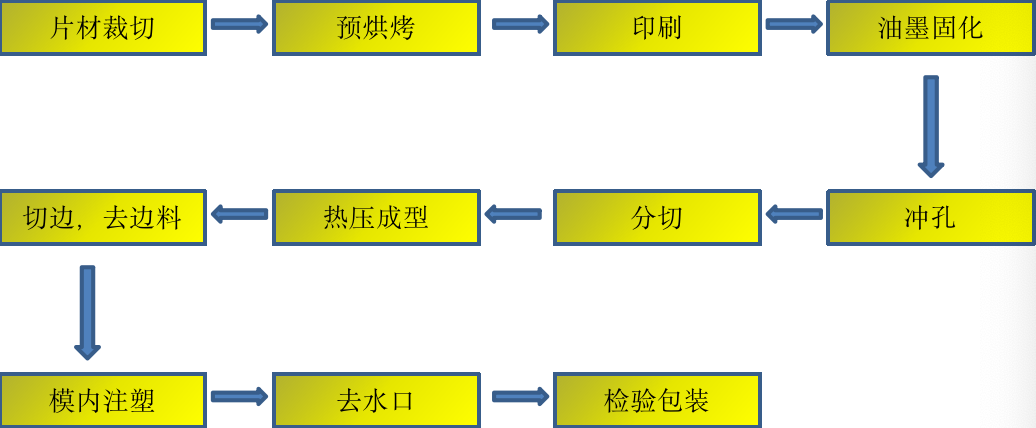

IML工艺流程:

IML工艺构成分层:

喷油是表面处理最常见的工艺之一。它不仅可以遮盖成型后制件的表面缺陷如划伤、飞边、气泡和结合线等,还可获得较好的外观及手感。相比其它表面处理工艺,喷油的成本相对低廉,应用非常广泛。

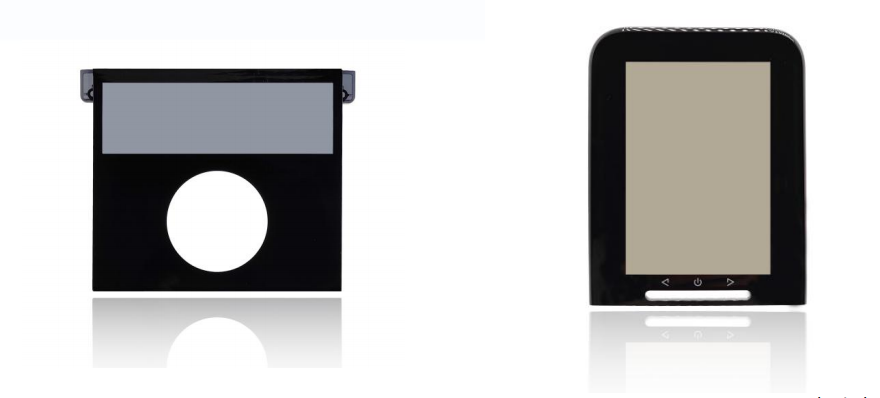

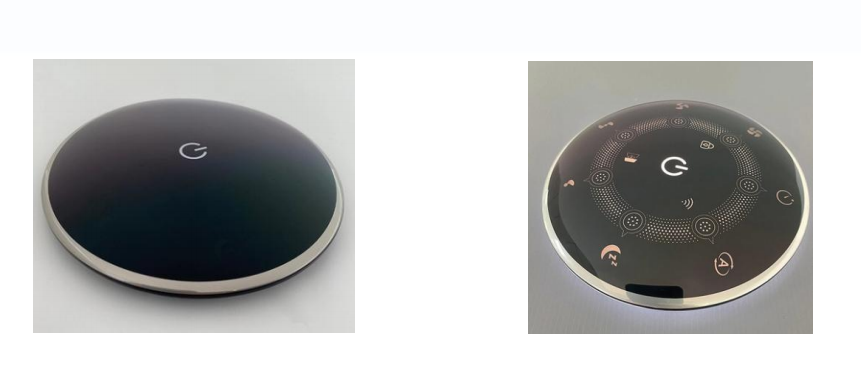

相对于喷油而言,IML/IMD工艺给人的印象是成本更高,结构受限。因此在工艺选择时常常被忽略掉。但实际应用中存在很多IML/IMD工艺比喷油工艺的性价比更高的场景。这里我们整理了一部分应用案例供大家参考、借鉴。

Summarize:

- Compared to spray coating, IML offers superior surface hardness, enhanced scratch resistance, and ensures that product colors and patterns remain vibrant and unfading over time.

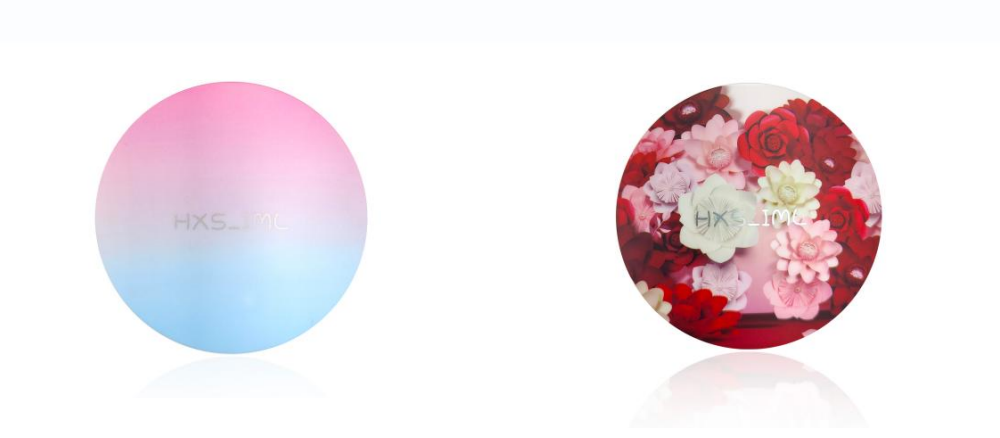

- The IML/IMD process offers a richer color texture and a wider variety of color options to choose from.

- Compared to spray coating, the IML/IMD process can achieve a multitude of colors and gradient effects, fulfilling more intricate aesthetic requirements.

- IML/IMD technology can be considered for virtually any scenario that requires both coating and light transmission.

- For products requiring multiple layers of spray coating, the IML/IMD process offers a more cost-effective solution.

- In scenarios that necessitate a combination of spray coating, screen printing, laser engraving, or electroplating, the IML/IMD process proves to be more cost-effective.

来源:深圳市和鑫晟科技有限公司 Alex Ouyang 13510827698

原文始发于微信公众号(艾邦新消费电子资讯):Alternatives to Spray Coating Processes in In-Mold Labeling Applications

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.