PCTG is a highly transparent copolyester material that is widely utilized in consumer products due to its superior physical properties and the absence of bisphenol A, particularly in cosmetic packaging and plastic drink cups. Its excellent flame-retardant characteristics make it a safer choice. In the e-cigarette industry, PCTG is primarily used for manufacturing oil tanks, heating bases, and casings. Its transparency not only enhances the aesthetic appeal of the products but also allows users to easily monitor the e-liquid levels, thereby improving the overall user experience. Although PCTG has found applications in high-end e-cigarette products, many manufacturers still prefer alternatives like PP or PC due to cost considerations. Special attention must be paid to drying and mold temperature when processing PCTG. The raw material should be dried in a vacuum dryer for 4 to 6 hours prior to injection molding, and the mold temperature should be maintained between 15 to 40°C to avoid compromising the material's performance. The recommended injection temperature is between 240 to 260°C to ensure the mechanical properties and clarity of PCTG are preserved.

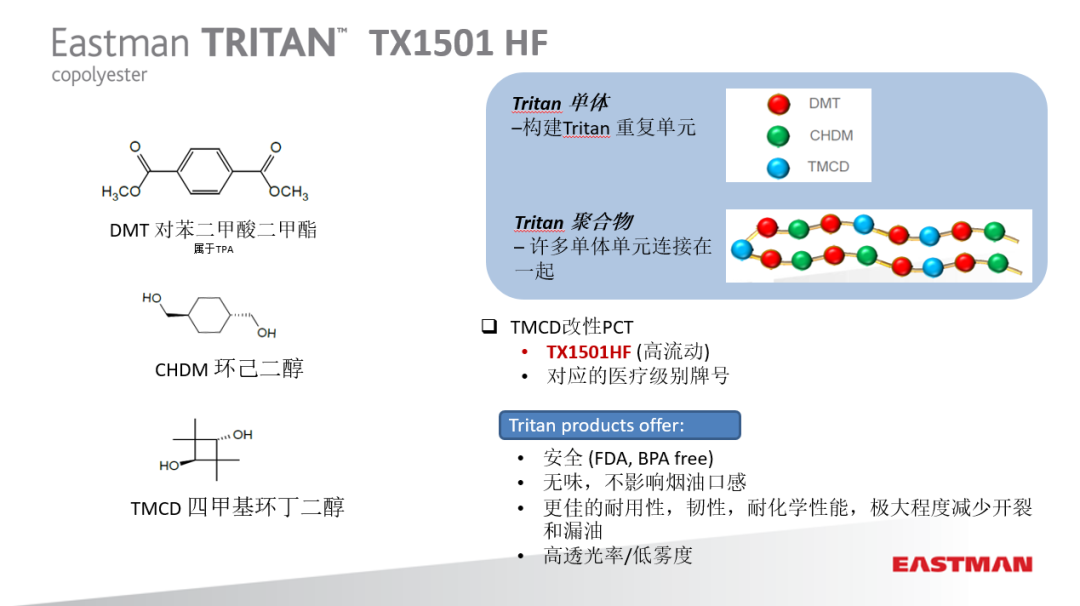

PCTG is a copolyester that has been widely used in a variety of consumer products due to its glass-like high transparency and superior physical properties.

图 伊士曼PCTG结构组分以及性能

图 伊士曼PCTG结构组分以及性能

This material is BPA-free, complies with food hygiene standards, and has good flame retardancy, making it ideal for cosmetic packaging and plastic drink cups.

at presentThe main companies that can supply PCTG raw materials include Eastman, SK, Dawn.

1. PCTG electronic cigarette application

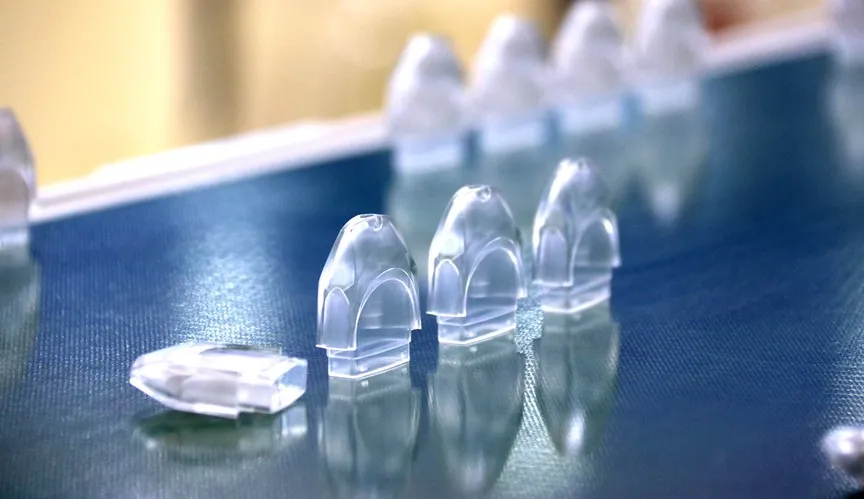

In electronic cigarettes, PCTG is mainly used to manufacture oil cups that require chemical resistance and high temperature resistance. In addition, PCTG is also used in heating bases, shells and other components.

起初,电子烟行业主要使用黑色半透明的PCTG烟油仓,这是因为烟油长时间存储容易氧化变色,影响用户观感。

随着技术和材料开发的进步,透明的PCTG材料开始被用于制造烟油仓,不仅用于换弹式电子烟,也逐渐应用于一次性电子烟中。透明烟弹和异形油杯的使用,不仅提高了产品的美观性,也方便用户直观地观察烟油量,提升了用户体验。

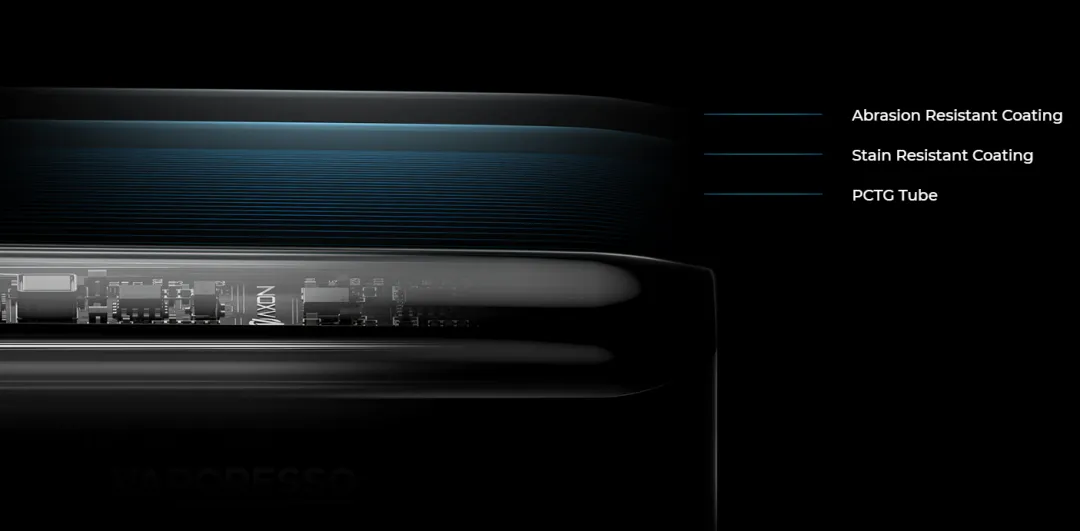

除了烟油仓外,PCTG由于其高透明和良好的机械性能,也开始被用于电子烟的烟杆外壳设计中。透明外壳不仅增加了产品的美观和科技感,也让电子烟产品更具吸引力。

然而,由于成本考虑,许多制造商还是选择使用PP或PC等其他透明塑料来制造发光的一次性电子烟外壳,而PCTG在高端产品线中的应用更为常见。

2. Precautions for PCTG processing

在加工方面,PCTG的处理需要特别注意。

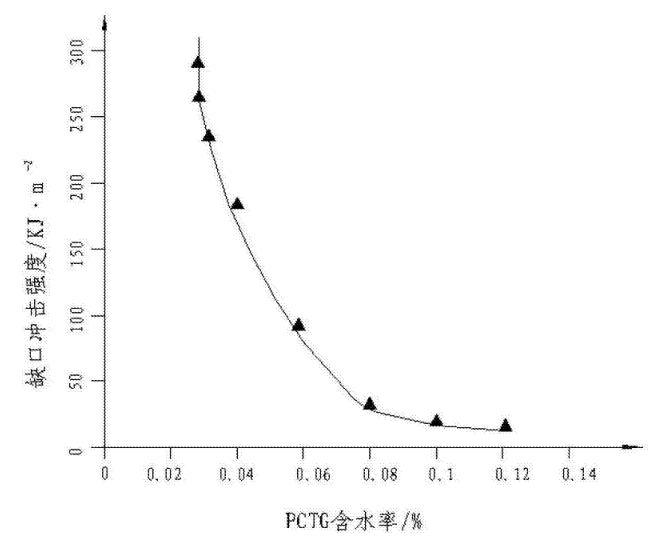

First, PCTG raw materials need to be thoroughly dried in a vacuum dryer for 4 to 6 hours before injection molding, and the recommended drying temperature is set according to the supplier's recommendations.Inadequate drying can cause the molecular weight of the polymer to drop and the additives to crack, affecting the color and physical properties of the molded part.

图 PCTG成品抗冲击强度与原料含水率关系曲线,源自专利 CN103481437B

图 PCTG成品抗冲击强度与原料含水率关系曲线,源自专利 CN103481437B

另外,PCTG的模具温度应控制在15-40℃之间,使用过高的模具温度会降低材料的性能。

During the injection molding process of PCTG, it is recommended to use the direct gate glue feeding method and avoid using hot runner, because long-term high temperature will cause serious degradation of the material. An ordinary screw-type injection molding machine can meet production needs. The processing temperature of the material is usually recommended to be between 240-260°C, which helps to maintain the mechanical properties and transparency of PCTG.

原文始发于微信公众号(雾化科技展):Application of PCTG materials in electronic cigarettes

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.