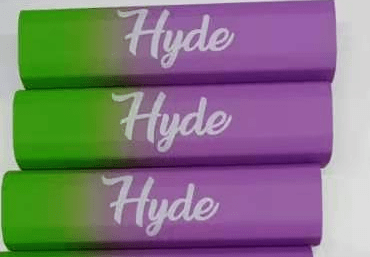

Gradient color spraying on electronic cigarettes is a common process that requires certain experience and skills. You must pay attention to the details of each link to obtain a better surface effect. The following is the process flow of common spraying plants:

-

Preparation Work:首先需要准备好喷涂设备和所需的颜料、溶剂等材料,以及待喷涂的电子烟部件。同时,需要确保喷涂环境干燥、清洁,以避免灰尘等杂质附着在涂层上。

-

Base Coating:先喷涂一层底漆,以保护电子烟部件表面和增加涂层的附着力。底漆可以选择与渐变色相近的颜色,也可以选择与渐变色形成对比的颜色,以达到不同的视觉效果。

-

Gradient Coating:使用喷枪从一个颜色开始,慢慢喷涂到另一个颜色,形成渐变效果。这需要在喷涂过程中不断调整喷涂距离、喷涂角度、喷涂压力等参数,以确保涂层渐变自然、均匀。 -

Define the Transition Area of Colors:在渐变涂层干燥之前,需要在涂层中确定过渡区域,以使涂层的颜色变化更加自然。可以使用各种方法来完成这个过程,例如使用遮盖物、喷雾胶等。

-

Glossing:等待涂层干燥后,使用透明的光泽漆进行上光,以保护涂层和增加光泽度。这需要注意上光的均匀度和厚度,以避免出现起泡或斑点等问题。

-

Confirm Quality:最后需要进行质量检查,确保涂层无气泡、无污渍、无裂纹、颜色均匀等,并且与客户的要求相符合。

来源:兄辉电子

原文始发于微信公众号(艾邦新消费电子资讯):Tips on the electronic cigarette spraying gradient color process

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.