The rapid loss of fragrance is a common pain point in current HNB (Heated Not Burned) products. This issue stems from the widespread use of liquid food-grade flavorings as aroma carriers, which have weak heat resistance. When exposed to high temperatures, these flavorings degrade and volatilize quickly, leading to short-lasting fragrance retention. To address this, the HNB brand MARSKISS has innovatively developed **"Latent Aroma Substance" technology**, rewriting the rules of fragrance delivery in HNB products.

“It’s like the difference between smelling an apple and actually eating one,” explained Zhan Baoming, founder of MARSKISS. “Current industry products offer superficial fragrance—akin to just smelling the apple—while our technology delivers the sensation of biting into the fruit.”

Latent Aroma Substance Technology: The Core Innovation Redefining HNB Fragrance

The story began in the early 2000s in a technology lab. Back then, the MARSKISS founding team had already started exploring harm reduction technologies for tobacco. After a decade of foundational research, the team discovered a breakthrough in aromatic plants: when processed through specific techniques, certain aromatic plants exhibited remarkable stability in fragrance components during high-temperature pyrolysis. This discovery gave birth to the concept of **“latent aroma substances”**.

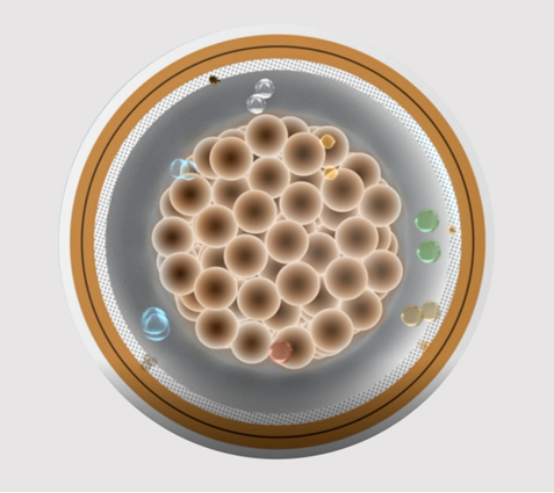

Through 12 meticulously designed processes—including enzyme deactivation, ripening, and aging—aromatic plants are transformed into solid latent aroma substances. Their honeycomb-like structure locks in fragrance molecules, which are gradually released upon heating, achieving a lasting balance between fruity notes and the natural aroma of tobacco. This technology restructures natural plant fragrance components, enabling staged release within the 200°C–400°C heating range.

In May 2023, MARSKISS hosted a product tasting event in Milan, Italy. Twenty-eight adult smokers of varying ages and backgrounds participated. Feedback was overwhelmingly positive, with most praising the product’s pure, long-lasting tobacco aroma and minimal residual odor in the mouth or surrounding environment post-use.

Precision Technology Behind the Smooth ExperienceTo tackle the dryness commonly associated with HNB products, the MARSKISS team developed two patented technologies:

1. Honeycomb Air Permeation Method: After extensive experimentation, the team uncovered the secret to balancing airflow and aroma delivery. Uniformly sized and arranged pores ensure stable, even airflow and consistent release of fragrance compounds.

2. Moisture Storage-Release Technology: A polymer-based honeycomb ceramic coating layer creates a sealed environment. Even under high temperatures, moisture in the tobacco segment is retained within the coating. When the segment dries, the stored moisture is released back into the latent aroma substances as fine water molecules through the honeycomb structure, ensuring moist, smooth vapor and a comfortable taste.

MARSKISS: Committed to Developing the Best HNB Products

ZILONG(S) PTE.LTD. (Zilong Singapore), headquartered in Singapore, is led by a core team of experts with over 20 years of experience in the tobacco industry. The company maintains long-term R&D collaborations with global tobacco giants and flavoring institutions.

Since successfully developing latent aroma substance technology in 2010, Zilong has dedicated itself to innovation in the HNB sector, driven by its mission to “create the world’s best HNB product for smokers.” In 2021, it officially launched the MARSKISS series, which incorporates three core technologies—**Tobacco-Reconstituted Latent Aroma Technology, Honeycomb Air Permeation, and Moisture Storage-Release**—all backed by 78 patent certifications.

Source: MARSKISS

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.